Sell Yuanying Tower Packing

| Price : | $200.00 |

| Quantity : | 500 (cubic meter) |

| Minimum Order : | 1 |

| Product Status : | New |

| Sample Available : | yes |

| Shipment Terms : | fob,cfr,cif,Negotiable |

| Payment Mode : |

T/T,L/C,cash,WesternUnion |

| Categories : | Chemicals, Chemical Filling |

| Posted By : | Yuanying Industry Limited |

Description

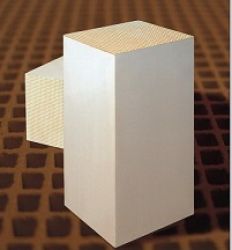

Tower Packing

Yuanying tower packing includes metal tower packing, plastic tower packing, ceramic tower packing.

Metal tower packing is made of carbon steel, aluminum alloy, stainless steel 304, 304L, 410, 316, 316L etc. Plastic tower packing is made of PE, PP, PVC, CPVC, PVDF, etc. Ceramic tower packing has the excellent acid resistance and heat resistance property, it can stand up to corrosion of various inorganic acids, organic acids and organic solvents, except HF, can be used in high or low temperature and strong corrosion equipment.

Tower packing includes the following products: pall ring, raschig ring, intalox saddle, conjugate ring, cascade mini ring, mellaring, interlocks, nutter ring, super mini ring, covering ball, berl saddle, lessing ring, Tri-Y ring, cross ring, spiral ring, hacketten, heilex ring, teller rosette ring, polyhedral ball, hollow floating ball, pentagon ring, hiflow ring, snowilaker, six prismatic ring, wheel ring, stacked ring packing, dixon (θ Ring), fenske spiral, glass spring packing, cannon packing, helipak, mcmahon packing, HY-PAK, sulzer gauze packing, mellapale packing, piercing hole mellapale, mesh corrugated packing, ceramic geometric packing, structured packing.

Pall Ring

Metal Pall Ring

Metal Pall Ring used in petrochemical industry is made of material like carbon steel, stainless steel or Aluminum alloy, etc. The product has features such as thin wall, heat resistant, high free volume, high capacity, low resistance, high separation efficiency and so on. It is especially suitable for rectification towers under vacuum to treat thermo sensitive, decomposable, polymerizable or cokable systems, so it is widely used in packing towers in petrochemical industry, chemical fertilizer industry and environmental protection, etc.

Material available: carbon steel, stainless steel including 304, 304L, 410, 316, 316L.

Plastic Pall Ring

Plastic pall ring's structure improves distribution of gas-liquid and its efficiency can be improved above 50%and only has half of pressure drop compared with raschig ring.

Pall ring has some advantages such as lower pressure drop, big flux, high effeciency, which HYPAK packing has better efficiency and lower pressure drop and better distribution of liquid compared with common pall ring.

Available material: PVC, CPVC, PP, PE, PVDF

It can be applied to various of device of isolation, absorption, deadsorption, common decompression such as toluene separation, ethylbenzene separation, isooctane separation and desulfurization system etc.

Ceramic Pall Ring

The Pall ring is a kind of new type and high efficient packing that is improved on the basis of the Raschig ring. Yuanying pall ring is a proven design that provides higher capacity and lower pressure drop than trays and other random packing. The opened cylinder walls and inward bent protrusions of the Pall Ring allow greater capacity and lower pressure drop than standard cylindrical rings. This open ring design also maintains an even distribution and resists wall-channeling tendencies. The interior and exterior contacting surfaces of the Pall ring provide for an effective distribution of liquids and gasses and resist plugging, fouling and nesting.

Raschig Ring

Metal Raschig Ring

Since 1914 when F.Raschig invented this type of ring for tower packing, Metallic Raschig Ring used in petrochemical industry has been developed extensively. The R-ring is now used in many applications, but particularly in supporting catalyst beds.

Metallic Raschig Rings are available in a wide range of carbon and stainless steels, 304, 304L, 410, 316, 316L etc.

Plastic Raschig Ring

There are kinds of materials for Plastic Raschig Ring, such as PP, PVC, CPVC, PVDF, PTFE, PE.

It has the following advantages:

a. Low pressure drop, excellent distribution, large void space, large flux, high mass-transfer effiency, low energy consumption, etc. Operational temperature range: Up to +150℃

b. Widely used in separation and absorption process, reducing pressure for device, deviating sulfur for the systems. It can easily isolate ethylbenzene, Toluene, trimenthypentane etc.

c. Package: Enhanced plastic super bag in jumbo bag, wooden case or carton. Other packing methord are available upon customers’ request.

Ceramic Raschig Ring

Raschig ring is a form of random packing and is used in commercial fractional distillation columns to reduce pressure loss (versus using trays), while maintaining good efficiency and economy. Raschig ring is proven in a wide range of mass transfer applications. Raschig ring structure provides one of the largest surface areas among tower packing options and handles heavy loading, process upsets and temperature shocks.

Intalox Saddle

Metal Intalox Saddle

Its advantages:

1) Improved efficiency due to lateral liquid diffusion and surface film renewal

2) Outstanding surface utilization in mass and heat transfer applications.

3) Shorter packed bed heights

4) Maximum piece-to-piece contact with minimal nesting

5) High strength to weight ratio allows up to a 15 meter bed height

6) Consistent performances due to uniform randomness

7) Free flowing particle design facilitates installation and removal via uniform randomizing

Plastic Intalox Saddle

Intalox saddle has characteristics of high void ratio, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific weight, high mass transfer efficiency and so on. It is widely used in the packing towers of petroleum industry, chemical industry, chlorine-alkali industry, coal gas industry and environmental protection.

Ceramic Intalox Saddle

Ceramic intalox saddle is improved from the arc saddle, it changes the both arched surface to rectangular surface and makes the interior and exterior radius of curvature different, this construction overcomes the problem of nesting basically, it makes porosity distributed even and improves the distribution of the fluid, greater capacity and lower pressure drop than Raschig ring.

Conjugate Ring

Metal conjugate ring is made of materials such as carbon steel, stainless steel or Aluminum alloy, 304, 304L, 410, 316, 316L, etc. Plastic conjugate ring available materials include PVC, CPVC, PP, PE, PVDF. Ceramic conjugate ring is made of alumina.

Conjugate ring draws benefits of ring and saddle packing. Owing to conjugate curve rib structure and appropriate length, there are point contact and aren’t intussusceptive between packing and tower or packing. Yuanying Conjugate ring has better hydrodynamics and mass transfer performance. It is applied to distillation, gas absorption, deadsorption system

Conjugate ring is used in both deep vacuum and high pressure towers. Conjugate ring is high performance random packing successfully used in mass transfer towers both small and large diameter. Conjugate ring is frequently used in deep vacuum towers where low pressure drop is crucial and also high pressure towers where capacity significantly exceeds conventional trays.

Cascade Mini Ring

Metal cascade mini ring is made of materials such as carbon steel, stainless steel or Aluminum alloy, 304, 304L, 410, 316, 316L, etc. Plastic cascade mini ring available materials include PVC, CPVC, PP, PE, PVDF. Ceramic cascade mini ring is made of alumina.

Cascade mini ring has features such as thin wall, heat resistant, high free volume, high capacity, low resistance, high separation efficiency and so on. It is especially suitable for rectification towers under vacuum to treat thermo sensitive, decomposable, polymerizable or cokable systems, so it is widely used in packing towers in petrochemical industry, chemical fertilizer industry and environmental protection, etc.

Cascade mini ring advantage

1) Reduced pressure drop

Reduced Pressure drop occurs because Cascade Mini Ring has its largest opening predominantly in the direction of the vapor/liquid flow which allows for easy passage, this reduces the pressure drop significantly.

2) Increased plant capacity

Increased plant capacity is the direct result of the result of the reduction in pressure drop that Cascade Mini Rings provide, as this moves the operating point further away from the “critical pressure drop point” at which flooding occurs. This is typically 1-2 in., wc/ft or 10-20 mbar/in). This effect allows additional vapor/liquid handling and therefore increases plant capability

3) Improved resistance to "fouling"

Improved resistance to fouling results from the directional positioning of cascade mini rings, (largest opening in direction of flow ) as any solids entering the packed bed are more easily flushed through the packing matrix.

4) Higher operational efficiency

Higher operational efficiency occurs because of the preferential orientation which ensures that in most of the ring surface are positioned vertically rather than horizontally, and this is also advantageous for mass transfer. High efficiency is dependent on as much of the available surface area as possible being effectively wetted. The underside of any horizontal surface in a packed bed or tower is naturally shielded from the liquid trickling down and is therefore not fully wetted, such dry surfaces play little or no part in the mass transfer process. Yuanying Cascade Mini Ring significantly reduces this effect, and therefore gives much higher plant operational efficiency.

Plastic Heilex Ring

Plastic Heilex Ring Materials: PP, PE, RPP, PDF, PVDF

Plastic Heilex Ring have large void rate, low pressure drop and low height of mass transfer unit, high extensive point, full contact of gas and liquid, low specific weight and high mass transfer efficiency. It is widely used in the packing towers, petroleum industry, chemical industry, alkali-Chloride industry, coal gas industry and environmental protection and etc.

Plastic heilex ring not only has the properties of large flux, low pressure drop, good corrosion-resistant & anti-collision strengths, but also has a filler not nested, the wall effect of small-and gas-liquid flow evenly distributed and so on. Heilex ring’s saddle shape openings of the main cone cylinder, increases surface area and porosity, and improves gas-liquid distribution in the packing bed.

Yuanying heilex ring used for gas absorption, washing and purification processes

Hacketten

Hacketten also called Polyhedral Hollow Ball, is made of PE, PP, RPP, PVC, CPVC, PVDF

Yuanying Hacketten has features such as high free volume, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific gravity, high mass transfer efficiency and so on, and the application temperature in media ranges from 60℃ to 150℃. For these reasons it is widely used in the packing towers in petroleum industry, chemical industry, alkali-Chloride industry, coal gas industry and environmental protection, etc.

Super Mini Ring

Super Mini Ring (HQM Ring) has better hydrodynamics and mass transfer performance. Yuanying Super Mini Ring is applied to distillation, gas absorption, deadsorption system, isooctane separation and desulfurization system, and so on.

Covering Ball

Plastic Covering Ball is kind of packing, designed based on the Hollow Ball. Compared with the Hollow Ball, Covering Ball has a rim around its surface. It has big void ratio, thermal proof, resistant to chemical corrosion. The height of pressure drop and transfering unit is low. Covering ball has high flooding packing factor, full liquid-gas contact, small bulky density, high transfer efficiency.....

Yuanying Covering ball is used in Petroleum, chemical engineering, chloralkali, coal gas, metallurgy, enviromental protection, electricity. It is used in horizontal acid storing cistern and storage or desalination water tank. Covering ball can reduce acid mist and the pollution of carbon dioxide and chlorine to the water.

Teller Rosette Ring

Teller Rosette Ring is made up of 12 small rings. Yuanying teller rosette ring has low pressure, great energy and high efficiency of mass transfer. Material includes PE, PP, PVC, RPP, CPVC and PVDF.

|

|